The layout of your warehouse is one of the most important things for maximizing efficiency and profit. You need to be sure that your warehouse does not limit your employees and actually benefits them. The best way to do that is by following these ways to optimize your warehouse layout.

Analyze Your Warehouse

The first step to the whole process of optimizing your warehouse is finding what needs improvement. There are many things you can do to test your warehouse for inefficiencies. Measuring pick times is a great place to start, as it will give you an idea of what might need optimization in your storage area. You should be on the lookout for heavy traffic areas as well, since they can be a common cause of congestion and time loss. You can look for unused space as well and see if it is something you can utilize later. Test the communication and the order management to see if there is any confusion, as that can waste a lot of time. Lastly, talk to the workers. They have the best idea about what they need to do their job more efficiently. Listen to their advice and keep it in mind as you plan the warehouse.

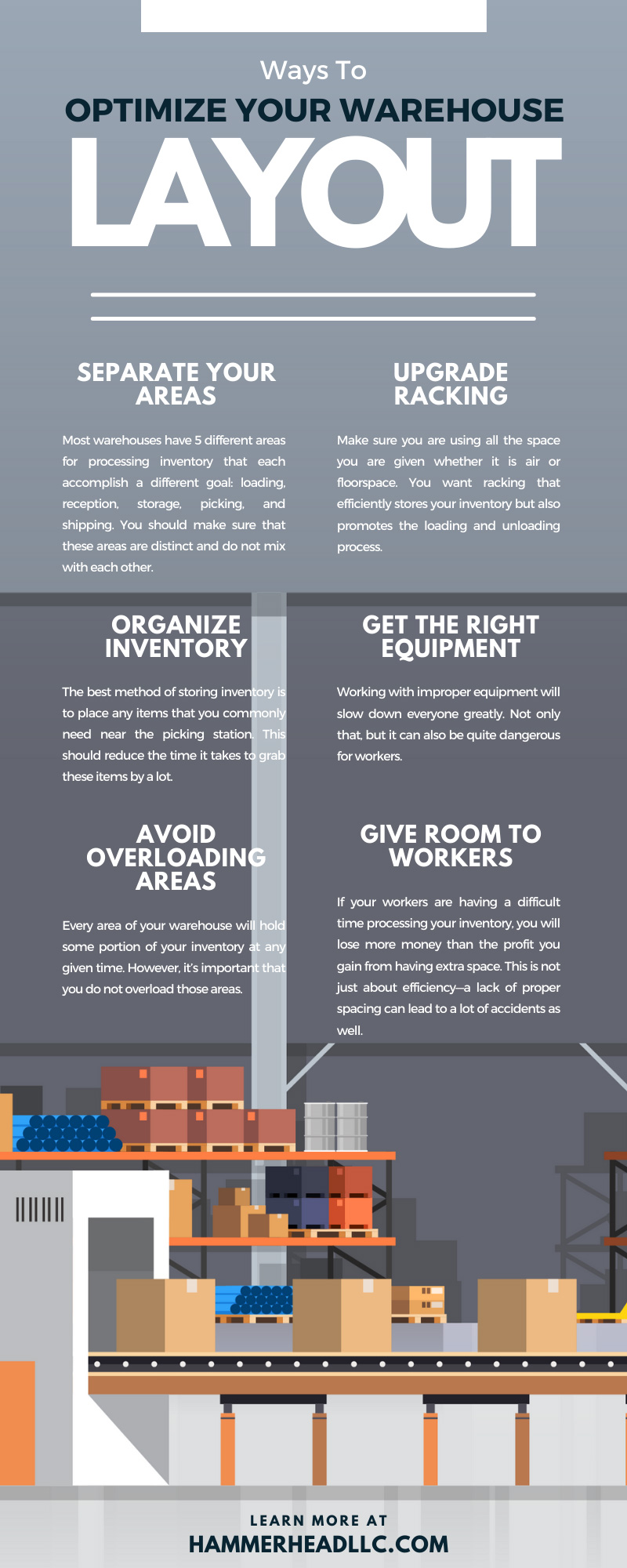

Separate Your Areas

Most warehouses have 5 different areas for processing inventory that each accomplish a different goal: loading, reception, storage, picking, and shipping. You should make sure that these areas are distinct and do not mix with each other. It is also important that you keep a single flow of items, as you don’t want incoming inventory to cross paths with outgoing inventory.

Aisles

Tackling your storage area is a large task and requires a lot of planning. One of the first things you should do for your storage is adjust the aisle width. Small, narrow aisle might seem optimal for storage space, but it slows down your workers; it can also make their job extremely difficult and dangerous. Give them enough room to navigate the aisle safely and keep their equipment in mind as well.

Upgrade Racking

You can lose a lot of potential profit to bad racking and storage areas. Make sure you are using all the space you are given whether it is air or floorspace. You want racking that efficiently stores your inventory but also promotes the loading and unloading process. Some places can benefit from automated warehouse storage systems, which load and unload inventory quickly and safely for employees.

Organize Inventory

A huge step to raising your warehouse’s efficiency comes from your inventory management. The best method of storing inventory is to place any items that you commonly need near the picking station. This should reduce the time it takes to grab these items by a lot. Saving you a lot of time and resources in the long run. You should also come up with a clear and simple labeling system that can help all of your employees locate the correct inventory.

Clear Loading and Unloading

A lot of items constantly flow into and out of a warehouse, that is why you need to keep these areas clear of any clutter and organize them carefully. Make sure that there is enough room for trucks to properly enter your warehouse’s loading or unloading area. You also need to leave enough room for any equipment, like forklifts, which can help move the inventory. Otherwise, everything will bottleneck and slow down processing.

Get the Right Equipment

Working with improper equipment will slow down everyone greatly. Not only that, but it can also be quite dangerous for workers. That is why you need to make sure that there is enough equipment to handle everyone’s workload and that it is the right equipment. You do not want workers to lift items that actually require the use of a forklift, as they will get hurt.

Look at Your Picking Process

The picking process of your warehouse can cost you a lot of potential profit if you don’t run it correctly. You want to make sure that you clearly define your picking area, and that it’s between shipping and storage. This will save a lot of travel time for your workers. Investing in machinery or equipment like conveyor systems can make your picking process much more efficient as well. You can also run special trainings to improve communication in the picking process, as this will cut down on mistakes and confusion.

Avoid Overloading Areas

Every area of your warehouse will hold some portion of your inventory at any given time. However, it’s important that you do not overload those areas. You should never go past 85% capacity in any given area, as doing so will cause a lot of congestion problems and prevent proper utilization of the area.

Give Room To Workers

Probably the most important thing you can do to raise efficiency in your warehouse is give room to workers. It can be tempting to use every inch you can for storage area, as it would seem like that would benefit your profit margin. But processing inventory is where your profit is really from—not in storing it. If your workers are having a difficult time processing your inventory, you will lose more money than the profit you gain from having extra space. This is not just about efficiency—a lack of proper spacing can lead to a lot of accidents as well. This means you can lose money because of worker injuries caused by limiting the space that workers have for proper mobility. Luckily, others test out the amount of room a worker needs to properly process inventory. On average, you should only use roughly 25% of the area for storage—the rest of the area should be for your employees.

By focusing on these ways to optimize your warehouse layout, you will find that your warehouse is a lot more efficient and that you can make more money. Not only that, but you will see that your workers will be happier after you have invested in creating a good working environment. You should also see a decline in worker injuries if everything is correct, as the warehouse should be safer for everyone.