There’s a lot you can do to increase the efficiency of your warehouse, increasing the potential profits of your business. You can make a lot of changes to increase your productivity, from investing in your workers and raising their safety measures to overhauling policies and communications. One way to improve your warehouse’s capability is by learning about and investing in the types of automated storage and retrieval systems (AS/RS).

Two Major Types

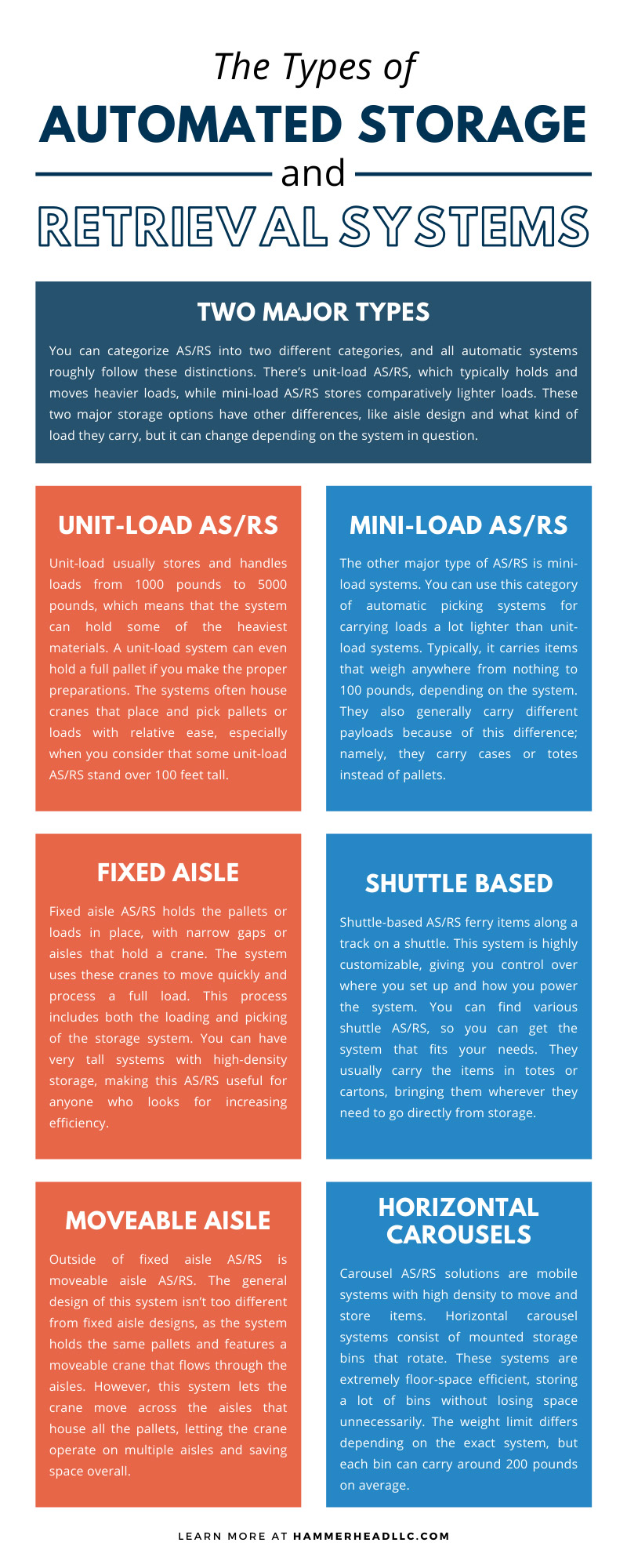

You can categorize AS/RS into two different categories, and all automatic systems roughly follow these distinctions. There’s unit-load AS/RS, which typically holds and moves heavier loads, while mini-load AS/RS stores comparatively lighter loads. These two major storage options have other differences, like aisle design and what kind of load they carry, but it can change depending on the system in question.

Unit-Load AS/RS

You should learn the general design tendencies of unit-load AS/RS for a better understanding of the systems you can get. Unit-load usually stores and handles loads from 1000 pounds to 5000 pounds, which means that the system can hold some of the heaviest materials. A unit-load system can even hold a full pallet if you make the proper preparations. The systems often house cranes that place and pick pallets or loads with relative ease, especially when you consider that some unit-load AS/RS stand over 100 feet tall.

Fixed aisle

Fixed aisle AS/RS holds the pallets or loads in place, with narrow gaps or aisles that hold a crane. The system uses these cranes to move quickly and process a full load. This process includes both the loading and picking of the storage system. You can have very tall systems with high-density storage, making this AS/RS useful for anyone who looks for increasing efficiency.

Moveable Aisle

Outside of fixed aisle AS/RS is moveable aisle AS/RS. The general design of this system isn’t too different from fixed aisle designs, as the system holds the same pallets and features a moveable crane that flows through the aisles. However, this system lets the crane move across the aisles that house all the pallets, letting the crane operate on multiple aisles and saving space overall.

Floor Robots

The floor robot is a unique system that brings the items to you on the back of mobile robots. This system has robots that carry portable shelving to operators that finish processing the items or materials. It’s a great way to limit risks to workers, but it’s not the fastest method since the robots can only move so fast in comparison to the other AS/RS. The loads that each robot carries can vary depending on the system and robot.

Mini-Load AS/RS

The other major type of AS/RS is mini-load systems. You can use this category of automatic picking systems for carrying loads a lot lighter than unit-load systems. Typically, it carries items that weigh anywhere from nothing to 100 pounds, depending on the system. They also generally carry different payloads because of this difference; namely, they carry cases or totes instead of pallets. These systems are great for places with limited floor space and can supplement other systems and cover the whole warehouse.

Shuttle Based

Shuttle-based AS/RS ferry items along a track on a shuttle. This system is highly customizable, giving you control over where you set up and how you power the system. You can find various shuttle AS/RS, so you can get the system that fits your needs. They usually carry the items in totes or cartons, bringing them wherever they need to go directly from storage.

Horizontal Carousels

Carousel AS/RS solutions are mobile systems with high density to move and store items. Horizontal carousel systems consist of mounted storage bins that rotate. These systems are extremely floor-space efficient, storing a lot of bins without losing space unnecessarily. However, most horizontal carousel AS/RS systems have a slow pace, making it great for systems that don’t need immediate results. The weight limit differs depending on the exact system, but each bin can carry around 200 pounds on average.

Vertical Carousels

Vertical carousels might sound similar to horizontal carousels, but they’re quite different. These large standing systems use a vertical track that loops the materials inside. This system doesn’t use a lot of floor space. There are dozens of different options you can consider and add-ons to this system, so make sure you find the one that’ll best fit your specific needs.

Vertical Lift Modules

A Vertical lift module or VLM is an ever-changing automatic system that alters itself to best fit whatever you carry. The system uses multiple layers to swap out and store items with relative ease. Surprisingly, each shelf is capable of carrying over a ton of weight, but it’s not fast with its throughput. It’s perfect for any place that experiences change because the system changes to fit your product. Also, they take so little floor space because they’re standing.

Vertical Buffer Modules

Vertical buffer modules (VBM) use totes to carry their items and for the picking process. These systems use a small mast to navigate all the bins inside and pick them at the operator’s request. You can also set up the VBM to sort and automatically store any totes you want to add. Additionally, you can often run loading and picking processes at the same time, making the system time efficient. VBMs aren’t just a simple addition to a storage area; you can make them a key feature in your storage area due to their scalability. It depends on what you want in your storage area.

These are the types of automated storage and retrieval systems that you often see, but there are other styles of AS/RS. Picking out the right automated warehouse storage systems for you is all about figuring out your area’s limitations and the materials you store and move with these systems. But with careful planning and customization, you can develop a great storage system that promotes efficiency and works with your needs. With this, you can elevate your business to a whole new level of efficiency.