Pallet racking is essential for warehouses professionals who want to optimize their storage space efficiently. Several types of racking methods are beneficial depending on your needs. The first step to choosing a pallet racking system is understanding the basic terminology and applications associated with this subject.

Deciding on the best storage method can seem intimidating, especially if you consider the mountains of information readily available to sort through. Fortunately, we have gathered all of the essential information you will need to make the best decisions for your warehouse. Here is an overview of static, dynamic, and automated pallet racking.

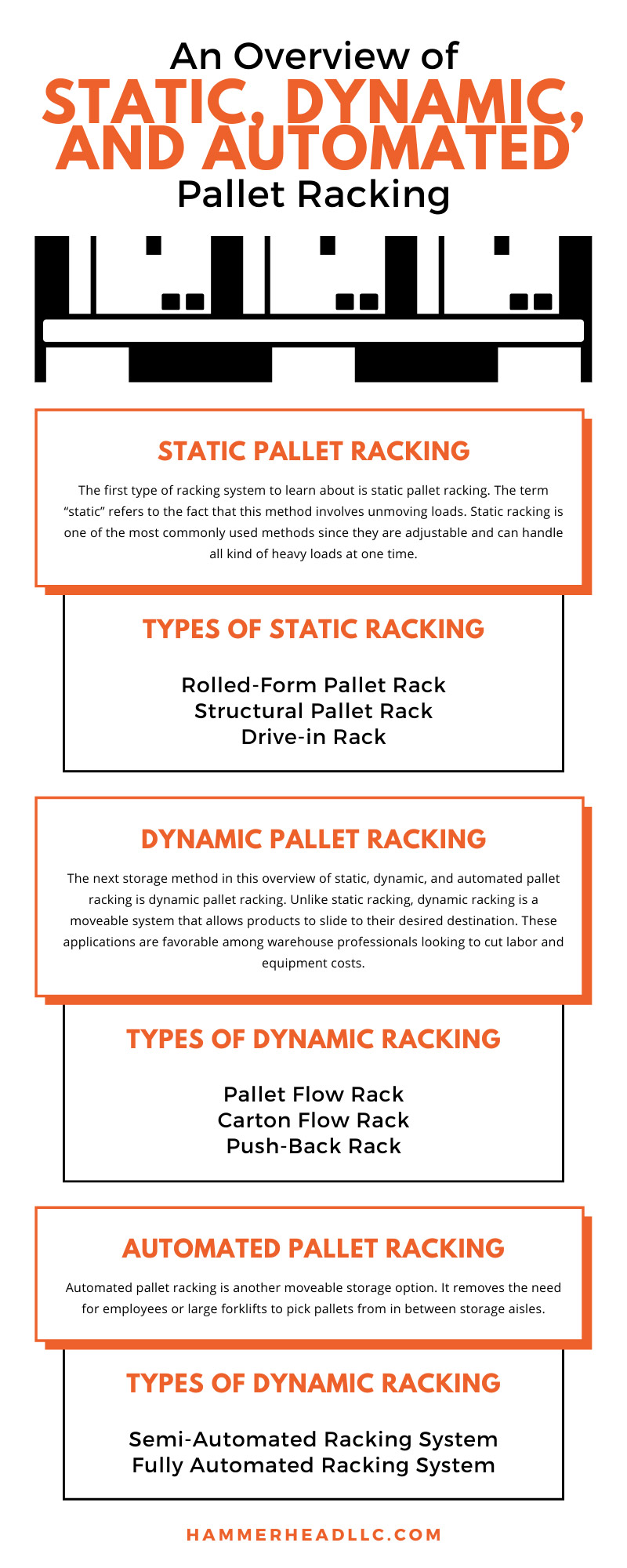

Static Pallet Racking

The first type of racking system to learn about is static pallet racking. The term “static” refers to the fact that this method involves unmoving loads. Static racking is one of the most commonly used methods since they are adjustable and can handle all kind of heavy loads at one time.

Think of static pallet racks like stationary shelves. They provide storage options that are easy to use, allow for quick product access, and are simple to organize. These racks are usually bolted to the ground and remain unmoving no matter what outside forces act on them. Warehouse professionals like this traditional option because of its stability and reliability.

Types of Static Racking

If you’re considering a static pallet racking system for your warehouse, you need to know your options. This is especially helpful knowledge to have when designing your storage space. There are three primary forms of static racking you should know. They are listed below.

Rolled-Form Pallet Rack

Manufacturers build rolled-form pallet racks with thin steel to handle medium-sized loads. Professionals prefer this static racking method because it’s cheaper to install and customizable to achieve specific storage goals.

Structural Pallet Rack

Structural pallets racks use strong, hot-rolled steel to support larger loads while withstanding heavy impacts. This racking method works with forklifts to lift and store heavy products and is perfect in harsh conditions that require more stability.

Drive-in Rack

Drive-in racks organize loads in a “last in, first out” manner. These systems can hold large quantities of loads in a highly-dense area and are a cost-effective storage option.

Dynamic Pallet Racking

The next storage method in this overview of static, dynamic, and automated pallet racking is dynamic pallet racking. Unlike static racking, dynamic racking is a moveable system that allows products to slide to their desired destination. These applications are favorable among warehouse professionals looking to cut labor and equipment costs.

Dynamic racks are also referred to as “gravity flow” systems because of the way they work with gravity to transport loads. Through the use of inclines and rollers, pallets can smoothly move through the storage space. This option allows loads to move into their picking positions once there is space to fill.

Types of Dynamic Racking

Warehouses can consider different types of dynamic options if they want to use this moveable storage method. The three most common dynamic pallet racking methods are listed below.

Pallet Flow Rack

Pallet flow racks are similar to drive-racks in that they are also a “first in, last out” system. Through the use of wheels, rollers, and breaks, pallets will move forward to fill the empty space left after the pallet in front of it unloads.

Carton Flow Rack

Carton flow racks are also a “first in, last out” system that uses inclined wheels and rollers to handle smaller loads. This method is ideal for sorting through boxes and filling orders in an assembly-style structure.

Push-Back Rack

Push-back racks are perfect for high-density storage needs. Loads are pushed back into pallet racks that move to accommodate the added material. Push-back racks allow for the stacking of pallets to free up necessary space.

Automated Pallet Racking

Automated pallet racking is another moveable storage option. It removes the need for employees or large forklifts to pick pallets from in between storage aisles.

Instead of stacking pallets directly onto the rack mechanism, forklifts place loads onto shuttles that transport and organize items deep into the rack. The reverse of the process occurs when it’s time to unload pallets from their location.

Types of Automated Racking

Two primary types of automated racking systems are on the market today: semi-automated and fully automated. Both forms use advanced technology to store and retrieve various sizes of loads in all kinds of warehouse storage layouts.

However, there is one main difference between the two types of automated racking methods. The semi-automatic option blends technology and manual labor to complete tasks, while the fully automated system completely removes humans from the equation. Warehouse professionals who have resources to spare find fully automated systems especially useful, while semi-automatic options exist for facilities that can’t or won’t eliminate their human element.

Which Method is Best?

Now that you know about the different types of pallet racking options, it’s time to choose which one will best serve your needs. This decision relies on several factors you’ll need to consider before investing in a pallet racking system. Each method comes with its own benefits and shortcomings, so make sure you weigh all of your options.

Static racking is perfect for fragile products that could sustain damage if not handled with care. Dynamic and automated racking systems take control out of employees’ hands and leave breakable materials vulnerable. However, static racks cannot function independently and always require some sort of manual labor. Static racks are also less sturdy and pose safety risks.

Dynamic pallet racking is a more efficient process than static racking because it speeds up the process and allows warehouse personnel more space to be productive in other areas and departments. They are also stronger and can reorganize pallets into their picking positions without the need for human interaction.

Automated racking systems are the best option for warehouse professionals who want to fully optimize their space. These racking systems also help lower labor costs and create a safer environment overall. However, there is a learning curve associated with this technology, and it can be expensive to install.

Most successful warehouses use a mixture of pallet racking systems to personalize their equipment to meet their unique needs. Don’t wait to incorporate methods that will increase your productivity. Hammerhead Material Handling is the top source for material storage racks, so contact us today!