There are many different types of racking systems available for storage areas, but one of the most popular is carton flow racking. These systems are quite useful for larger storage areas that have a lot of workers picking items frequently. To learn more about these racks, use this as a guide to carton flow rack systems and how they work.

What Is a Carton Flow Rack?

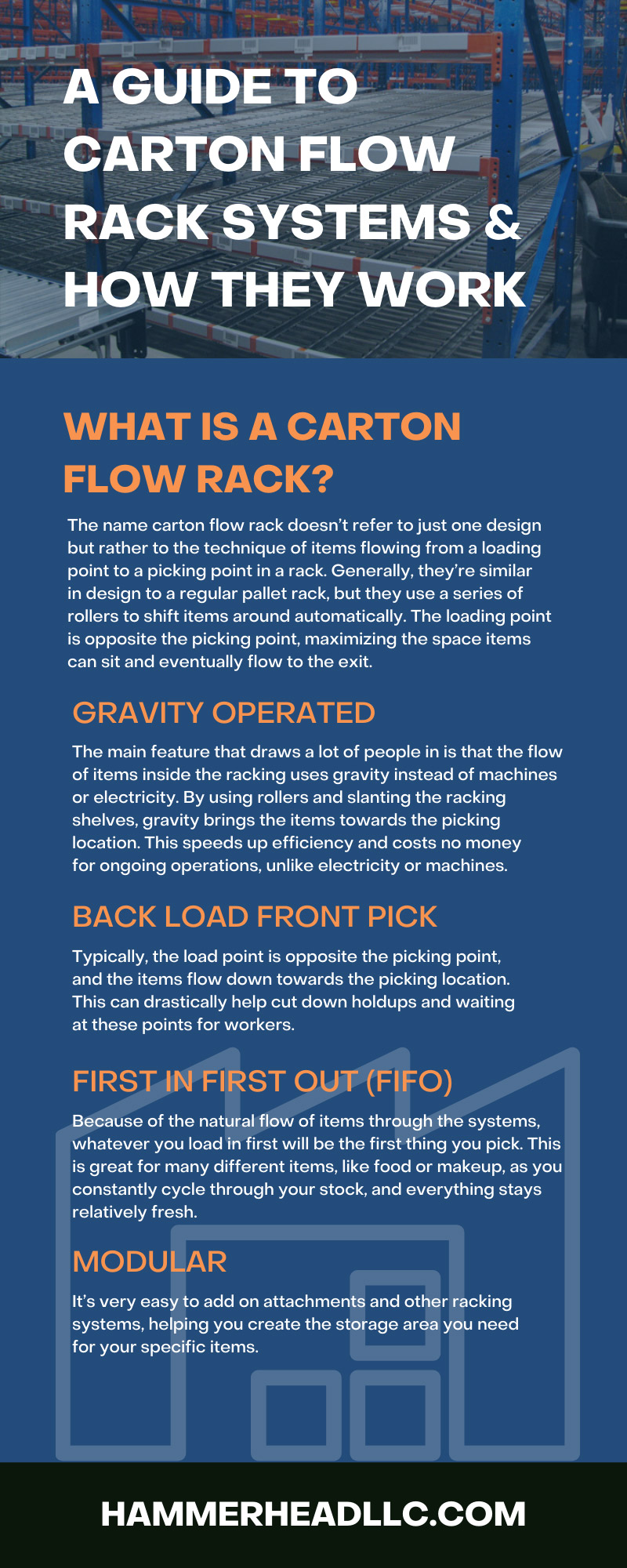

The name carton flow rack doesn’t refer to just one design but rather to the technique of items flowing from a loading point to a picking point in a rack. Generally, they’re similar in design to a regular pallet rack, but they use a series of rollers to shift items around automatically. The loading point is opposite the picking point, maximizing the space items can sit and eventually flow to the exit. In this next part, we’ll cover some of the other defining features of carton flow racking systems.

Gravity Operated

The main feature that draws a lot of people in is that the flow of items inside the racking uses gravity instead of machines or electricity. By using rollers and slanting the racking shelves, gravity brings the items towards the picking location. This speeds up efficiency and costs no money for ongoing operations, unlike electricity or machines.

Back Load Front Pick

Another key feature of carton flow racking is the fact that the load point is separate from the picking point. Typically, the load point is opposite the picking point, and the items flow down towards the picking location. This can drastically help cut down holdups and waiting at these points for workers.

First In First Out (FIFO)

Because of the natural flow of items through the systems, whatever you load in first will be the first thing you pick. This is great for many different items, like food or makeup, as you constantly cycle through your stock, and everything stays relatively fresh.

Modular

The next defining feature of a carton flow rack is the modular nature of these racking systems. It’s very easy to add on attachments and other racking systems, helping you create the storage area you need for your specific items.

The Benefits of Carton Flow

The next part of this guide to carton flow rack systems and how they work will talk more about the benefits of using a carton flow system for your storage area. Even if you don’t use just these racks for your storage, many places can vastly improve with the addition of just a few of these racking systems.

Different Racks

One of the main benefits of carton flow racks is the variety of racking designs you can make and use in your storage systems. This variety means you can mix and match your systems to design the perfect storage area for you and your materials. There are many different racking designs, and you can easily mix these racks with many different rack systems as well.

Low-Effort, High-Efficiency Systems

These racking systems are great for workers as well, helping them accomplish their picking and loading quickly. A good system will help your workers both load and pick items at much greater speeds than normal pallet racks systems. This is where these racking systems become a great investment for businesses, as they save money on workers and can fulfill more orders than before.

Worker Safety

Storage areas are rife with worker injuries, costing employers a lot of money each year and risking the life and health of workers. These systems can help alleviate some of the common issues with employee health, as the picking system can promote good health. A good carton flow system has employees both load and pick stock from safe heights, even when done in rapid succession. This can help reduce cases of repetitive stress injuries, especially when paired with worker training on safety and preventative measures. A proper investment into a good carton flow system involves a system that keeps your workers safe.

Inventory Control

Another benefit of carton flow racking is the ease of inventory management over other systems. Organization is a lot easier as certain racks only take certain inventory. It becomes a lot easier to track and organize all your items as the locations for everything are already set when you plan the area. Additionally, FIFO methods mean that you constantly go through your inventory, so old items don’t just sit around wasting space.

Clear Traffic Flow

Organizing the flow of traffic through a storage area is a difficult task and extremely important for both efficiency and safety. The more people who walk the same paths, the higher the likelihood of issues arising due to the traffic. Because of the picking and loading locations of the carton flow systems, separating the traffic to these areas becomes a lot easier. This makes storage layout a lot easier for everyone and can help employees work efficiently as well.

Same Time Output and Input

Another benefit of the different sides for input and output is the fact that two people can work the rack at the same time. Typically, one person must wait when someone else operates a racking system, as there’s no room for both employees. However, this system lets employees use the racks at the same time, one for loading and one for picking, thus increasing overall efficiency.

Variety of Stock

One of the great things about carton flow racking is the variety of items that you can store in these systems. Almost any material or product can be in these systems if you buy the right racking. You can even get custom systems that can accommodate your specific stock, vastly increasing the space utilization of your storage area and organizing your inventory at the same time.

This is what the carton flow storage system brings to the table and how it operates. Although they may not be useful for every product you store, every storage area can benefit greatly from adding a few into their storage. Now, if you’re looking for any carton rack systems for your storage area or need another racking solution, you can always talk to us here at Hammerhead for the assistance you need.