To properly plan and fully utilize your warehouse, you first need to calculate the storage amount you can use. You must know how to calculate storage capacity of a warehouse, but that canbe quite a chore. Here are the steps to do so.

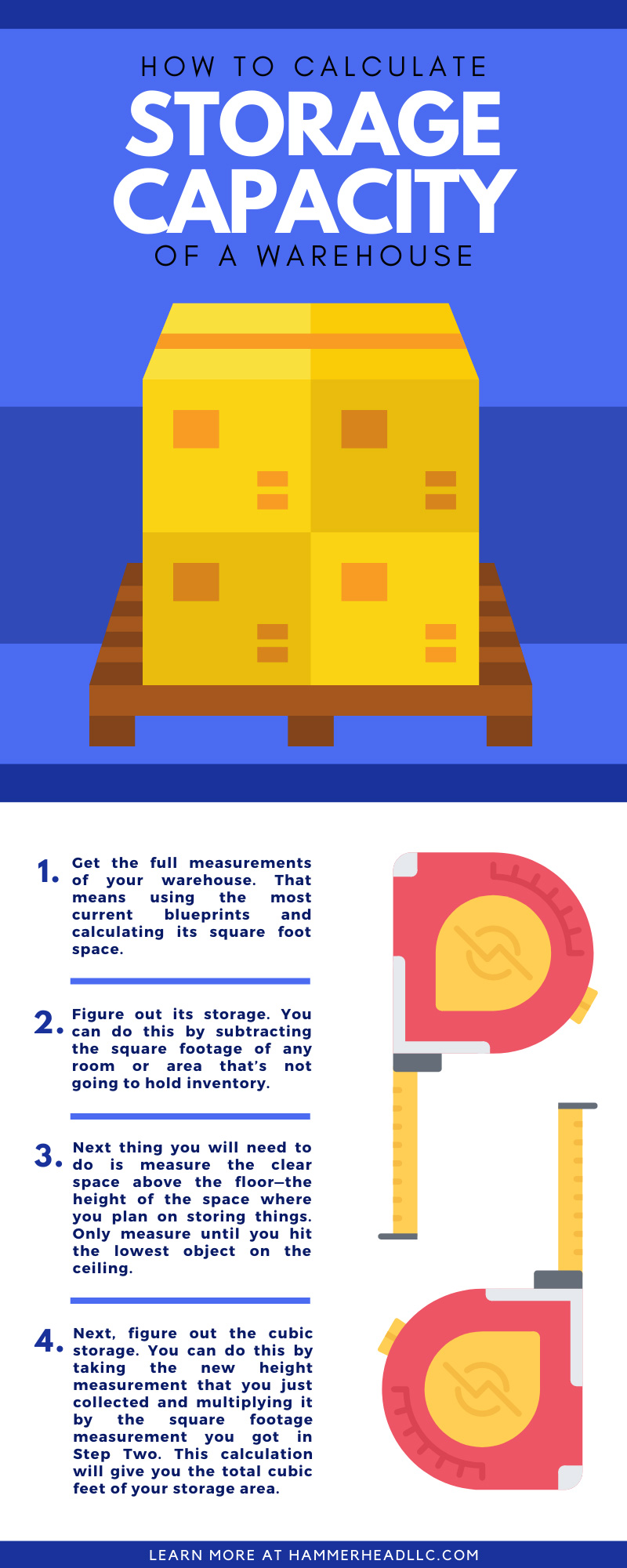

- Get the full measurements of your warehouse. That means using the most current blueprints and calculating its square foot space. This process can be quite complicated if you have to do the calculations yourself but usually the blueprints will have the calculations already done.

- Once you calculate warehouse capacity, figure out its the storage. You can do this by subtracting the square footage of any room or area that’s not going to hold inventory—bathrooms, office, and the like. What you will be left with is the square foot area to use for storage.

- Next thing you will need to do is measure the clear space above the floor—the height of the space where you plan on storing things. Only measure until you hit the lowest object on the ceiling. If your warehouse uses hanging lights or has beams running across the ceiling, measure to those objects. If you don’t, measure all the way up to the ceiling.

- Next, figure out the cubic storage. You can do this by taking the new height measurement that you just collected and multiplying it by the square footage measurement you got in Step Two. This calculation will give you the total cubic feet of your storage area.

When you calculate storage space in warehouse settings, ensure the total cubic feet of storage doesn’t overflow with the things you need to store in your warehouse. There needs to be plenty of room to work in so workers can safely and quickly navigate your storage area and access whatever they need. This means you should plan to have only a portion of the storage space utilized; 25 percent is the common and safest amount. More than that and you’ll find your workers will work slower from all the clutter and even possibly injure themselves inside the mess.

The Best Ways To Utilize Your Storage Space

The first step in organizing your storage space is to plan. Make sure your calculations are correct so you’re optimized and in working order. Begin this by measuring the footprint of your storage methods. If you are using pallets you’ll need to measure the space they take up (including shelves.) Measure the capacity of each storage unit, either shelving or pallets in this example. Doing this will show you how much inventory you can carry. Next, multiply this measurement by the amount of shelving or pallets to understand how much inventory space you have. As we’ve mentioned above, make sure this utilizes about 25 percent of the total cubic storage area. Once you know how much shelving or pallets you can use, you can start to plan the layout of the storage area. Remember, give enough room and access to the inventory so workers can safely move about and get what they need. (It might be tempting to cut corners but all that will accomplish is a slower workforce and increased labor costs.)

It’s important to plan your storage space carefully—but also consider every option. There are several common types of pallet racks that prove useful for different types of storage:

- Selective racking is a very common type but isn’t capable of stacking multiple pallets due to its lack of depth. However, this means the pallets are accessible from several sides of the rack.

- By design, drive-in racking has most of the storing and moving of the inventory done by forklifts. Usually built to only be accessible from one side, drive-in racking can stack multiple pallets onto one level.

- Carton/pallet flow racks are built with a roller or wheel system that moves packages from the back to the front of the rack whenever you remove a package. This allows for the quick removal of inventory. The first items placed in the rack are the first ones accessible for removal.

- Mobile racking is also an option. This kind of rack has wheels that can move the entire rack, usually on tracks, to provide extra mobility and access to the inventory.

It’s important that you invest in some quality material handling racking systems if you want to fully utilize your warehouse. These racking systems keep storage optimization in mind and can really help you use all your space efficiently.

If you’re trying to renovate your storage system you should start by properly utilizing all your clear height storage space you can add tons of extra room. If you start to use higher racking you will need to leave enough room for machinery such as forklifts. This is why it is so important to use only 25 percent of the area— without it, machinery will have a difficult time gathering any inventory. Some other things you can do to increase your storage is to shift pallets around. Raise lighting or other objects that dangle from the ceiling if you need room for more shelves. Automated storage and retrieval systems can also take up space. (Although, they can save workers time and energy by retrieving inventory, or doing shelving, for them.)

One way to avoid a lot of this hassle and make sure that everything runs smoothly is to trust a group of professionals such as Hammerhead. Here at Hammerhead, we’re more than capable of giving you the storage space you need for your work. As single source provider, you can come to us for every step of the process.

A good storage space is well thought out and keeps the needs of not only the inventory in mind but also tIf you calculate warehouse capacity often, you can keep the needs of not only the inventory in mind but also the needs of your workers. Now that you know how to calculate storage capacity of a warehouse and how to utilize its storage area, you can make these plans. The utilization of a storage area is key to running any good warehouse; it saves money and tons of resources. Keeping labor costs down and promoting efficiency will improve your business and take it to the next level. Consider our quality storage products for all your warehouse and business needs! Additionally, our expert services will better help with your warehouse space utilization.