Learn about why a custom racking system is important to have in your warehouse, the different kinds of racking available, and more!

1. Understanding Warehouse Racking Systems

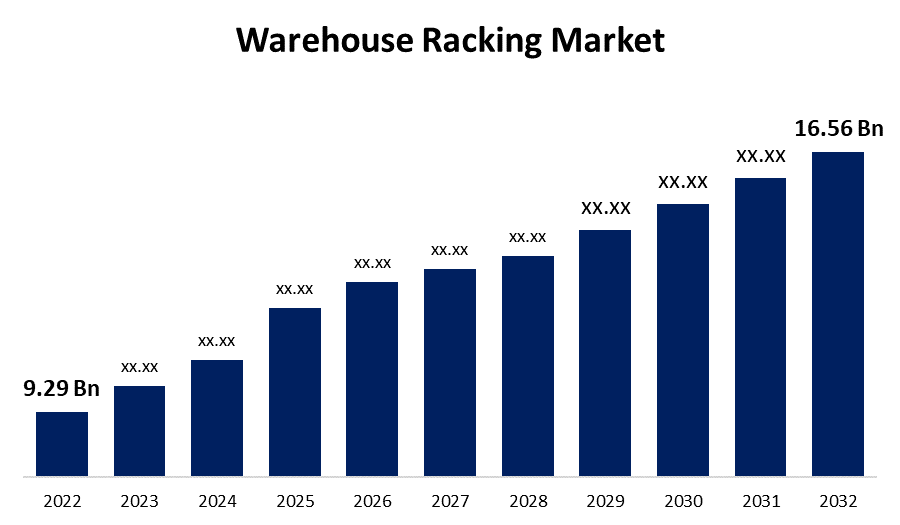

Racking systems play a crucial role in organizing and maximizing storage space in warehouses. These systems offer various types, each catering to specific storage needs and space constraints.

Next, let’s dive into how to select the best racking system for your needs…

2. Selecting the Best Rack System

Choosing the perfect rack system involves considering several factors such as storage requirements, safety, budget, and available warehouse space.

Here are some options to consider:

• Selective Pallet Racks: This cost-effective option provides direct access to every pallet at any height, making it ideal for warehouses with high SKU volume storage needs.

• Cantilever Pallet Racking: Perfect for storing lengthy objects or furniture, offering a space-saving solution for items like lumber, plywood, and metal.

• Record Storage and Archive Shelving Racks: Tailored for storing boxed files and records, maximizing storage density for paper records and legal documents.

These options only scratch the surface of the diverse range of rack systems available. Feel free to check out our racking options here!

Let’s move on to the benefits of warehouse racking systems.

3. Benefits of Warehouse Racking Systems

Investing in the right warehouse racking system offers numerous advantages:

• Maximized Space Utilization: Optimizing vertical storage space minimizes the need for additional storage facilities.

• Streamlined Inventory Management: Organized storage locations and labeling systems facilitate efficient inventory tracking, reducing errors.

• Improved Productivity: Well-designed layouts and streamlined workflows enable faster item retrieval, enhancing order fulfillment rates.

• Enhanced Safety: Secure storage and clear access aisles minimize the risk of accidents, promoting a safer working environment.

• Flexibility and Scalability: Modular racking systems can be easily adjusted to accommodate changing business needs.

• Cost Savings: Efficient warehouse management leads to lower overhead costs by minimizing wasted space and optimizing processes

Ready to get started on your project?

At Hammerhead Warehouse Systems, we’re dedicated to helping you leverage the advantages above and optimize your warehouse operations for success. We understand the significance of efficient warehouse management in order for your business to thrive.